At Inside Systems, we are committed to using sustainable and environmentally friendly packaging materials.

As a member of the Danish interest organization Environmentally Friendly Packaging Materials, we are constantly seeking ways to minimize the use of packaging materials and protect the environment. You can read more about the organization – note that the website is in Danish.

As a starting point, we try to use undamaged packaging again to reduce the consumption of materials. Especially cardboard boxes, which can often be reused – but since they are required to have full integrity to protect the goods, they cannot always be reused. If we assess that the boxes can’t be used again, we convert them into package filler to protect the goods – we do this with the help of a Kobra FlexPak. Kobra FlexPak cuts the cardboard boxes into pieces and perforates them, thus transforming them into high-quality, environmentally friendly and stable packaging filling.

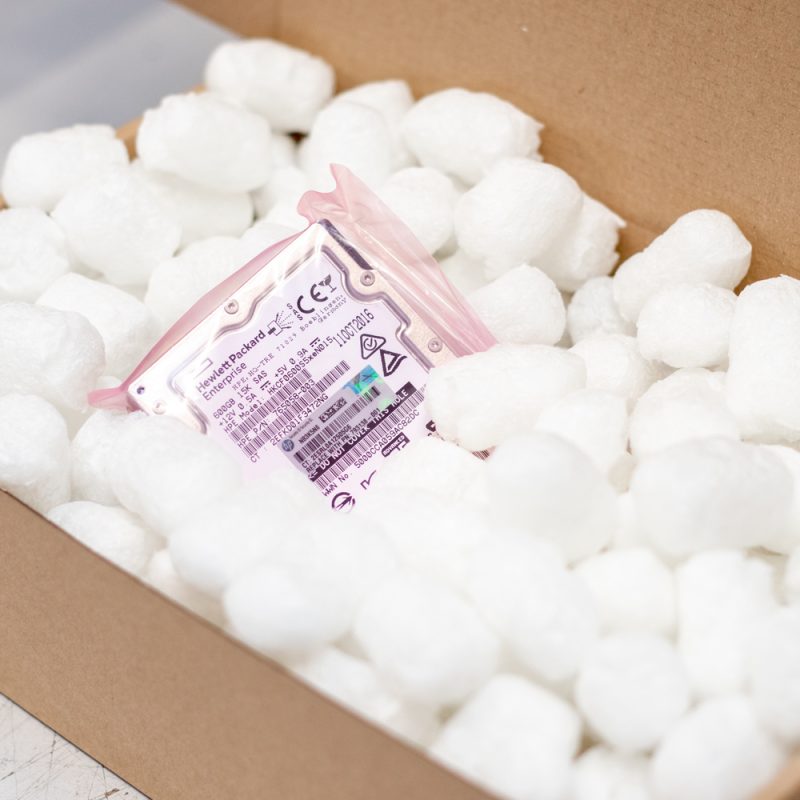

We also use Biofill – the natural box filling

Using Biofill as a box filling material has several advantages. One of the main benefits is that it is more environmentally friendly than traditional plastic fillers. Biofill materials can be biodegraded by microorganisms under specific conditions, reducing the environmental impact of the material compared to traditional plastics which can take hundreds of years to degrade in nature.

Biofill is a cylinder-shaped filling material that is intended to protect products in boxes and shipments. Biofill is pourable and suitable for silo systems.

Biofill is a type of biodegradable plastic that is made from renewable resources such as corn starch, sugarcane, or other plant-based materials. These materials are biodegraded by microorganisms under specific conditions into carbon dioxide, water, and biomass.

This Biofiller is the only filling product on the Danish market with the DIN EN 13432 certification, which is possible because it is produced from natural ingredients. This also means that Biofill can be disposed of both with organic and ordinary household waste.

When Biofiller material gets DIN EN 13432 certification, that means it is suitable for industrial composting and its environmental impact is much lower compared to traditional plastics. It is also confirmed that it is safe for the environment and human health.

As Biofill materials are becoming more popular as a more environmentally friendly alternative to traditional plastics, certifications like DIN EN 13432 will play an important role in ensuring that these materials are safe and effective for use in various applications.

A few facts about Biofillers:

- Biofill is easy for the end user to dispose of.

- Biofill has a high shock absorption capacity.

- Biofill has the market’s fastest flowability.

- Biofill is antistatic and free of dust.

- Biofill is produced in Denmark.

- Biofill is produced without plastic and other oil-based chemicals.